All the processes and technologies in the Kfar Menachem Metal Works are the most professional and advanced in the market. There are 5 main technologies, each suitable for different products, depending on the type of product and the purpose of use. In each of these technologies we use advanced state-of-the-art machinery to obtain a high-quality product to suit your needs, and help you perform complete and accurate electrical work.

Hot forging

The classic technology we use for metal design is the process where the raw material is softened by heating, and then redesigned in the desired shape, offers advantages in the durability of the material and its properties over the years, and also prevents the formation of air pores that are common when using inferior technology, such as casting.

Friction welding

The winning technology that is used to make cable shoes. This technique combines two metals by friction and pressure. This technology can also help us in cases that require fast execution and delivery.

Machining

CNC machines chip processing is one of our most advanced technologies. In this technique the raw material comes as a large metal block larger than the final product, and it undergoes “carving” and “filing” just as in the creation of art, until the final result. Our uniqueness is in the skilled and expert team operating these machines.

Design and manufacture of moulds

All moulds for metal and plastic parts are designed and manufactured at our factory, not by an external manufacturer. The result: precise and high-quality moulds that shape the finished product with a meticulous quality.

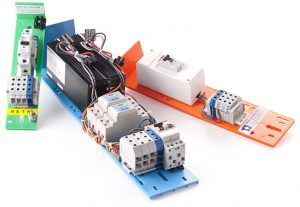

Plastic injection moulding

The plastic products at the Plant are manufactured through our subsidiary – Maglan. Our plastic injection technology is the most advanced and precise, and produces the highest quality products in the market.